How AI is Transforming the Future of Packaging Design

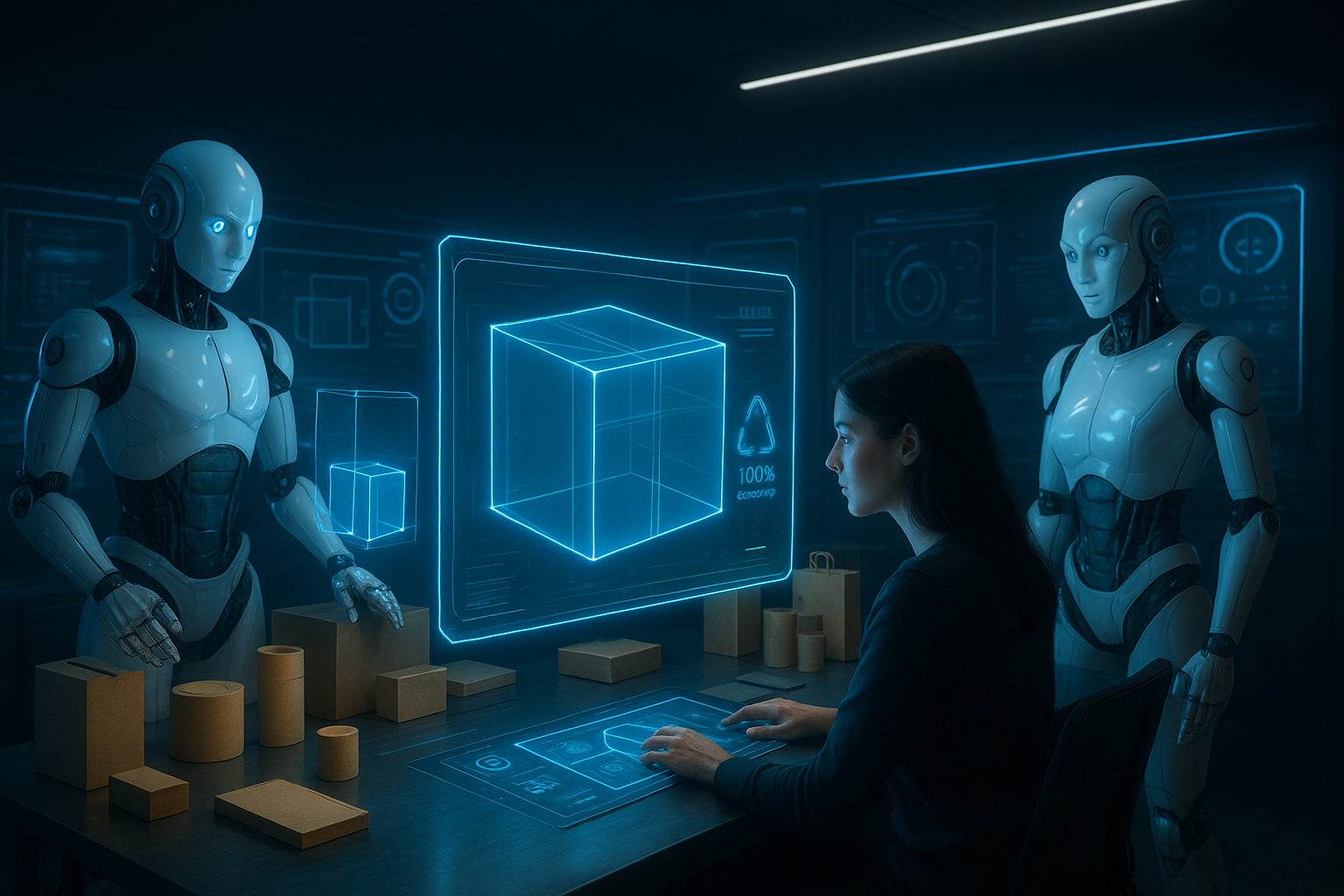

It is hard to accomplish a perfect packaging design that balances aesthetics and practicality. As, it requires efforts to manufacture a visually striking box with minimal material usage at a lower cost. Over and above, the client’s demands for sustainability and supply chain efficiency have made this balance an impossible task to achieve. Under this immense pressure, brands are seeking the help of Artificial Intelligence. AI is not a futuristic concept or an automation tool. It is a creative partner with thousands of options for various specifications. From creating packaging designs from scratch to predicting color palette, running durability tests, and suggesting structural designs to reduce cost. AI algorithms have restructured the whole packaging practices. In this blog, we will explore how AI packaging design has transformed instinctive packaging into a data-driven and hyper-efficient science.

Why does AI packaging design come first?

The use of generative AI tools has become a common practice in the packaging industry. A clear evidence of adopting this technology is a survey. This survey suggests that in 2025, the AI packaging market is valued at $2.84 billion. And it is expected to reach $6.9 billion by 2032. The reasons behind the ubiquitous use of AI packaging design are quite evident. It provides data-driven insights by analyzing consumer preferences. Reduces costs and errors by minimizing human errors. And most importantly, AI packaging plays a crucial role in optimizing sustainability by recommending eco-friendly materials and streamlining logistics.

How AI optimizes the custom packaging workflow

Packaging doesn’t just involve box manufacturing. It is a long process that starts from consultation and ends with the final shipping of custom boxes. The emergence of artificial intelligence packaging design has made this process efficient and error-free. Moreover, it improves the quality of custom packaging boxes that build brand recall. Let’s shed some light on every aspect of artificial intelligence.

AI generative consultation

The very first step of packaging is requesting a quote. Responding to this quote is a lengthy procedure. As it requires a lot of effort to gather price rates, material suggestions, and cost-effective design ideas. Therefore, companies take 24-48 hours to reply. However, AI has streamlined this process autonomously. Machine learning, an application of AI, consists of algorithms that interpret the user’s question accurately. And then, it analyzes market trends, design complexity, and material cost to provide competitive pricing. This digital innovation has reduced the time to respond for businesses. Rather than days, now it takes a few minutes to provide an accurate cost estimation.

As AI continues to evolve, there is a potential for multimodal response generation. This means instead of a simple textual response. Soon, there will be a possibility to reply with an image or video clip for a better understanding of a quote.

Data-driven and predictive design

Humans are predictive. Not for other humans but for AI-powered tools. Therefore, to meet the consumer’s demands, companies make the best use of this technology to design their custom retail packaging. What happens is, AI-powered algorithms or tools analyze consumer behavior, market trends, purchase history, and cost efficiency. With the help of this dataset, it further suggests packaging colors, layout, and unique design elements to manufacture a visually striking box. Moreover, companies can run a predictive test of artificial design. Generative AI can provide a virtual simulation of how customers will react to their packaging.

Beyond aesthetics, AI has played a meticulous role in packaging functionality. It can create hundreds of design options based on shape, size, and style as per the predefined parameters. Designers just have to enter their requirements into an AI application. Like protection criteria, net weight, or material durability. And as a result, it can predict your packaging dimensions, recommend robust materials and suggest a structurally stable design.

Sustainability and optimization

When it comes to sustainable practices in packaging, there is no compromise. AI has performed remarkably in this parameter, too. It has led the packaging industry towards more eco-friendly solutions. From material selection to reducing environmental waste. AI-powered tools have streamlined every step of the packaging industry. Like:

- AI algorithms can analyze a product’s fragility and weight to suggest the most suited eco-friendly material. Moreover, it can optimize the dimensions to reduce waste by 15%.

With AI-powered tools, companies can evaluate packaging material, design, and labels. It will help in manufacturing a packaging that is easy to recycle. - Logistic management is a concerning challenge for companies. As an organized inventory helps in the distribution of goods and ensures product safety. With artificial intelligence, a structured inventory is attainable. AI can predict efficient ways to pack products and offer real-time customization. This is helpful in reducing inventory waste and stockpiling.

- With real-time data like distance, fuel consumption, and traffic congestion. AI-powered tools can suggest the most efficient route for shipping. In this way, companies can save a lot of fuel costs and reduce their carbon footprint.

Virtual prototyping and testing

AI has transformed free sampling and 3D mockups into a simulated packaging test. This has made the production process faster and cost-efficient for the companies. In virtual prototyping, a digital twin of a box is designed to test its durability in software. It is then subjected to various stress tests to check its feasibility in the real world. The test includes:

- Drop test

- Humidity testing

- Stacking strength

With virtual prototyping, packaging companies are able to detect structural weakness. Furthermore, it has reduced printing errors, improved product quality, and led to faster turnaround times. Thus, AI is a bridge that connects functionality with perfection.

Integration of AI packaging design with IoT

A major intervention seen in the packaging industry is the fusion of AI and IoT. For custom packaging boxes in bulk, it is a transformative strategy. For example, embedding IoT sensors on custom food boxes can collect data on the product’s condition throughout the supply chain. Whereas the AI algorithm can analyze product history to calculate the remaining shelf life. As a result, AI-powered tools can send trigger alerts to the stakeholders. So that they can take necessary action to prevent product spoilage.

Another smart use of AI and IOT is the RFID tags, NFC chips, and QR codes. The addition of these features in an AI packaging design gives a unique digital identity to a packaging. Customers can scan through these codes to make online payments, verify product authenticity, and detect tampering.

The real challenges of artificial intelligence for custom packaging boxes

The ease and convenience offered by AI-powered tools is beyond appraisal. However, there are some practical and ethical challenges in its implementation.

- The first and foremost issue is privacy. AI models like machine learning or predictive analytics use large volumes of data to analyze consumer behavior. First thing, it is a taxing job to handle such a large amount of data. Secondly, a minor bug or error in a system can compromise the data security that often leads to privacy breaches.

- Although generating an AI packaging design is a quick process. However, it lacks human nuance. This means these designs fail to build an emotional connection between the brand and the audience. Thus, brands struggle to communicate their values, goals, and personality.

- AI models only analyze market trends and historical data to make predictive designs. These tools are inapplicable for mentioning complex product details. Such as nutritional facts about food items, legal warnings for CBD and tobacco products, and ingredient lists for beauty products.

- An AI packaging design is a result of creative artwork from different brands and designers available on the internet. This poses a risk of copyright infringement that mostly leads to legal battles between businesses.

- Lastly, implementing AI solutions to custom retail boxes requires a huge investment. That further needs maintenance costs and technical expertise to use it. Thus, it is hard for small and medium-sized enterprises to afford such high-end technology.

Conclusion

Implementation of AI models in custom packaging is like a vision come true. Where companies can manufacture custom boxes without human intervention from scratch. Currently, these models have made slight interventions by offering design optimization, cost-efficiency, and sustainability. But who knows what more innovations are to come in the future with AI-powered tools. Embrace this technology today to seize its future opportunities.

.jpg)