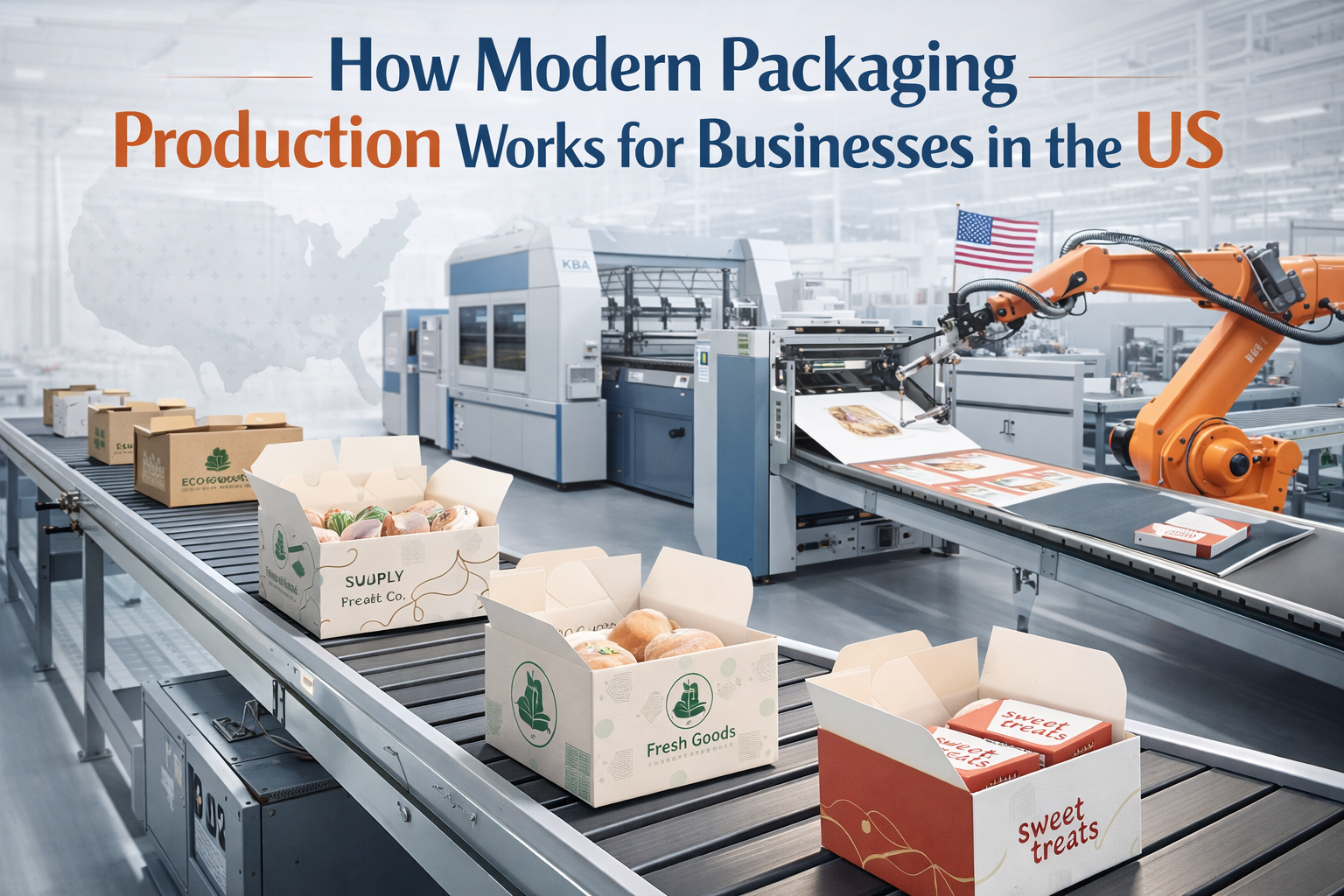

How Modern Packaging Production Works for Businesses in the US

What is an indispensable phase for all companies that manufacture products? It’s the production. The staff has to be meticulous and accurate to generate flawless outcomes. Thus, this avoids negative reviews and saves brands from degradation. Besides, businesses are of various sorts. And one of them is the box suppliers. Packaging boxes are basically their products. Also, they ensure that the packaging production conforms to the standards and wholly satisfies their clients.

The guide below is a deep dive into the fundamental steps. This is what we follow as well. The purpose of creating this content is to make the procedure transparent to the businesses opting for product packages from US suppliers. How are the strategic designs formed? Or what embellishments work perfectly for uplifting the buyers’ box-opening experiences? You will find the answers below.

Key Steps in Modern Packaging Production for American Businesses

The procedure is a blend of various aspects. It combines creativity and mechanical speed to manufacture an abundance of boxes. Nevertheless, among the pre-production steps is amassing the clients’ requirements. Maybe they submit the detailed version, by exactly stating the type of box style and colors. If not, it’s up to the box suppliers to decide on what suits the business needs the most.

Creating a Strategic Design & Structural Engineering

The packaging and manufacturing are very much dependent on structural engineering. Before cutting the single sheet of paper, it is vital for designers to create a two-dimensional blueprint. The correct term is dieline. This flattened-out structure helps to determine every tuck, flap and fold. Also, the professionals depend on software to stress-test the structure.

Moreover, one of the steps is prototyping. It is highly critical, as it incorporates digital cutting tables and forms a physical mockup. Hence, the businesses can easily examine whether or not the product can fit inside the box. They also determine the capabilities or strength of the packaging. For instance, to be able to survive the drop test.

The Right Substrate for Strength & Sustainability

Then comes the base material. The businesses have to know the caliper, which is also the thickness measured in points. Besides, such a choice relies on the goal. For example, the solid bleached surface or SBS is the best pick to obtain a clean look. It further aids in providing a high-quality printing surface. Therefore, it is apt for the pharmaceutical and cosmetic industries in the country.

On the other hand, there is a kraft board. It is made of recycled fibers and is famous for its distinctive as well as natural charm. The appearance is typically natural brown. And this option is perfect for brands embracing green values. So, it is highly nature-friendly and helps businesses to solidify their position in the market.

The Three Advanced Printing Technologies

This step showcases the brand identity. There are three technologies currently popular in the US. The first is offset lithography, which is suitable for high-volume folding cartons. Brands aiming for intricacy or detail should surely go for this option. Also, it even provides a very impressive color consistency.

Furthermore, there is digital inkjet that has gained popularity in the packaging production. It eradicates the need for printing plates. Therefore, it is appropriate for short-run seasonal packaging. Lastly, there is flexography. It is quite fast and affordable for gigantic industrial runs. Hence, for corrugated shipping boxes and mailers, give this technology a go.

Finishing & Embellishments for Protection & Decoration

After printing, the sheets require a final coat. There are multiple varnishes and coatings that safeguard as well as beautify the sheets. For instance, shipping boxes to long-distance areas often leads to scuffing. It is the friction that causes physical damage. Oftentimes, containers are very close to each other. Therefore, it is essential to protect their surfaces and varnishing definitely assists in preventing damage.

Moreover, there are a multitude of very striking embellishments. The best custom packaging company like us can undeniably guide and offer such options to meet your business requirements. For example, embossing gives a raised texture on the surface, while debossing is just the opposite. Conversely, foil stamping is for metallic shine. Ultimately, these embellishments produce premium results. They are thus imperative to impress high-end buyers.

Feeding Sheets into High-Speed Die-Cutters

This is the genuine transformation phase. There are high-speed machines in which the sheets are fed. Then a steel rule die, which is among the very important packaging production equipment, cuts a shape out of the sheet. It is a big, razor-sharp cookie cutter. Thus, you can expect precision.

In conjunction with this cutting process, creasing of sheets also occurs. It prepares the substrate to be folded. Although precision is crucial in every step, it is a highlight in this one. A slight error can lead to jamming of the boxes in the automated fulfillment line. Additionally, millimeters are the unit for measuring this precision.

Flat-Pack Fulfillment for Saving Storage

After the packaging has been die-cut and glued, it goes through the shipping and storing processes in an unassembled state. This is an important strategy for a low-cost supply chain. Storing the boxes flat means there is the absence of trapped air. Therefore, the brands can maintain higher stock levels without expanding their warehouse.

In addition, the shipping vehicles can contain more units this way. This minimizes the inbound trips from the box creators to fulfillment centers. Thus, leading to a lowered carbon footprint and aligning with the nature-safe values. And due to them being stacked tightly, they form a solid form of material and do not get damaged easily.

Latest Trends in US Packaging Production

- Integrating QR codes for smart packaging

- Mono-material solutions for simplifying recycling

- Easy-to-open and shipping-ready designs for e-commerce optimization

The integration of QR codes directly into the print layer leads to digital portal creation. This allows for inventory tracking and assists consumers to verify authenticity. Moreover, brands can exhibit their content and share instructions on how to utilize their items. Hence, it strengthens their bond with the buyer.

On the other hand, mono-material packaging is also a current trend in American packaging production. The whole package is made of a single material family, making it recyclable. Another aspect is offering the ease of opening the container by eliminating the outer layer. Also, the packaging is tested to ensure that it maintains the original state of the product inside.

Conclusion

Determining packaging production steps is essential to wholly rely on the box supplier. There are many of them, as stated above. For instance, forming a strategic design with the use of software. The designers construct a blueprint and test the structure. Furthermore, professionals have to find the substrate that is right for the business demands. Like obtaining a clean look and eco-friendliness.

The next step involves the printing techniques. And three of them are the most typical in modern packaging: offset lithography, digital inkjet and flexography. Next, we explained the importance and kinds of embellishments. Also, the article shared the use of die-cutters and the advantages of shipping the boxes flat. QR code integration, mono-material solutions and shipping-ready designs are among the current trends in the production of US packaging. For more, head to the official blog of the Boxit Packages.

.jpg)