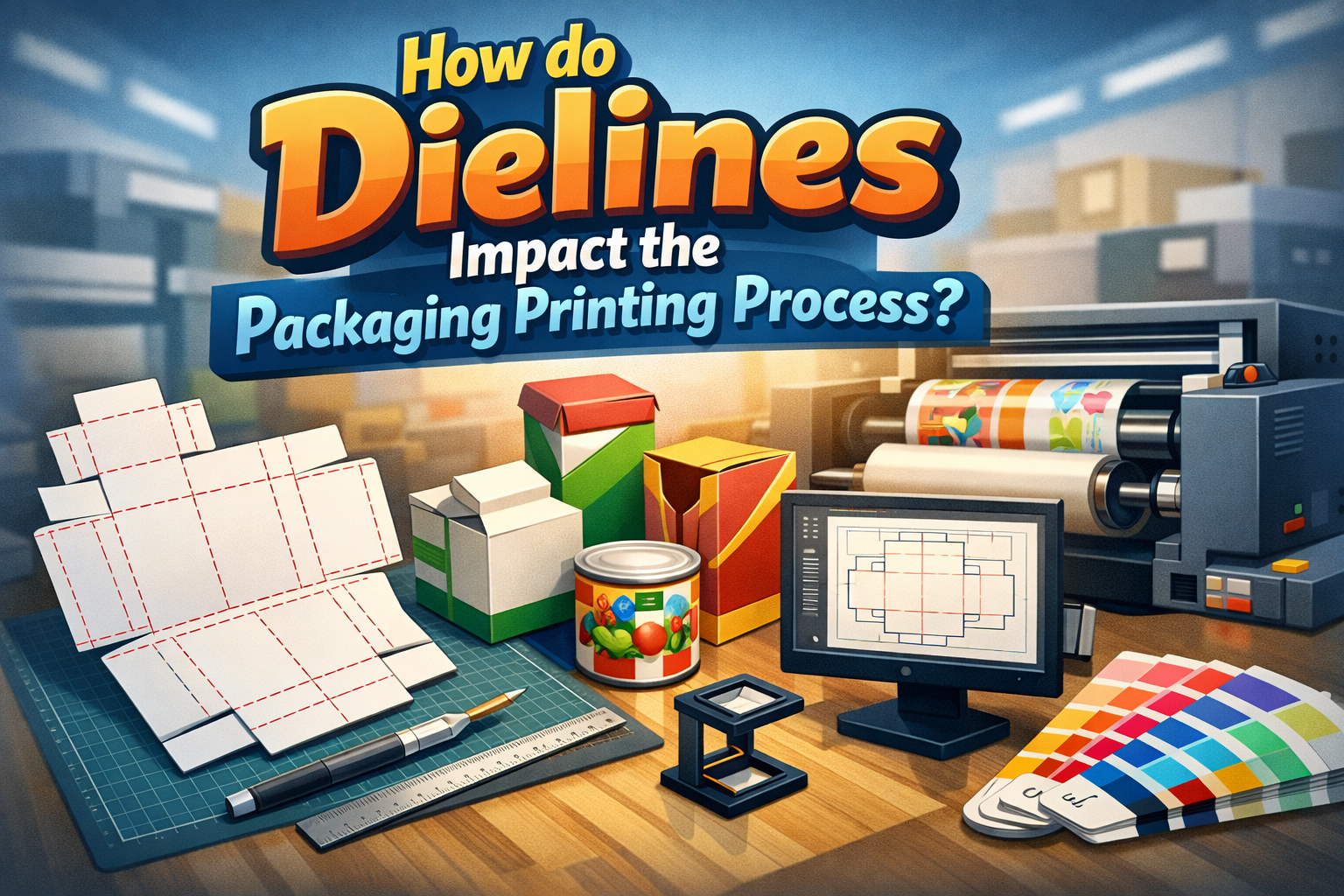

How do dielines impact the packaging printing process?

When building a luxury home, a rough hand-drawn sketch is not enough for construction. You need a proper master floor plan to get every room, window, door, and other architectural features in place. The packaging industry also operates under the same conditions. You cannot print a functional, high-quality box without a precise dieline. A dieline is like an architectural blueprint. It is the exact point where a flat, two-dimensional sheet of paper is mathematically engineered to become a three-dimensional experience. In simple words it’s a critical bridge between creative vision and physical manufacturing. Without the dieline you cannot create perfect artwork and flawless packaging. Also if the dieline is off by even a millimeter, your million-dollar brand identity can literally fall apart at the seams. Therefore, understanding the role of dielines for packaging is the foundation of professional packaging.

Read this blog to further explore what the dieline is, why it’s important, how to create one, and how dielines affect the printing process.

What is a dieline?

Just as an architect relies on a blueprint to build a skyscraper. A packaging printer relies on a dieline to ensure where the blades will cut, where the machinery will crease the material for folding, and where the printing ends. To be more precise dielines for packaging are actually vector files that include the packaging size, scale, and dimensions. They further include the location of visual elements, placement of creases, cut lines, glue tabs, and folds, manufacturing notes, and bleeding lines.

The lines of dielines for packaging and their function

In printing and packaging, there are three types of lines used to create cardboard box dieline. Dotted perforation lines, cut lines, and fold lines.

Cut lines

When preparing dielines for custom printed boxes, cut lines are the most critical markings on the box layout. They are also known as the trim lines because they represent the exact path where the material will be cut and take the desired shape. The right dimensions of these lines are very important. Because if the lines are off even by 1mm. You may not get the accurate shape of a die cut box, your product might not fit inside, or flaps might not overlap.

Fold lines

Fold lines also known as crease lines are the markings that indicate where the flat piece of paper or substrate will be bent, scored, or folded.

Dotted perforation lines

Perforation lines are small slits or holes punched into the substrate. Graphically they are represented by dotted or dashed lines and are color-coded as green or magenta. The purpose of color coding is to create distinction between solid or crease lines. Where the function of these lines is to:

- Create a “tear-away” section.

- Convert standard shipping boxes into a “Ready-to-shelf” display.

Essential steps before you prepare dielines for packaging

No matter how beautiful and unique the design of your die cut box is. It will not be useful if it refuses to close or ensure product safety. Therefore, while preparing your dielines for packaging do consider the following features.

Size

The size of your product and packaging is directly related to dielines dimension. If a dieline is created exactly similar to the product’s dimensions. Then your box will be compact and it will be hard for the product to fit. Therefore, while preparing dielines you must account for “wiggle room”. Moreover, do leave a space of 1.5mm to 3mm if your packaging includes inserts or dividers.

Weight

Weight of the product determines how the box should be sealed at the bottom. If the product is lightweight, you don’t need any safety flaps. But if the product is heavy the dieline must include reinforcement zones and interlocking flaps to create a stable base.

A step-by-step guide to flawless dieline creation using Pacdora

Creating a dieline with Pacdora involves generating a precise vector template that acts as a roadmap for die-cutting and folding machines. Let’s explore this workflow for drafting a functional dieline.

Measure accurate box dimension

For précised height, width, length, and measurements of tabs and flaps of a box, start by calculating the right dimensions of the product. Once you get the size of your product, take a box or package that fits your product or resembles your design. Unfold its tabs, flatten it out and measure it. This will provide you with the measurements you need for creating a dieline. If you do not have a pre-made box sample. Then you can also use online tools like Template, Pacdora, or Cefbox to generate the dielines for packaging.

Pick the right software

Once you get the right measurements for your dielines, the next step is the design. For this you can use Adobe illustrator or ArtisoCAD. These software are the ideal option for crafting clean, scalable lines and shapes. Speaking of illustrators, use the following tools to create the dielines.

- Rectangular tool (To make panels)

- Pen tool (Used for making connections)

- Solid stroke (Use it for marking cut lines)

- Dashed stroke (To create folding and perforation lines)

Add distinctive branding elements

Apart from necessary lines, dielines also include some visual elements that help in building unique brand identity. You can use Text (T), Selection tool (V), and swatch panel to add typography, logo, and colors. However, do re-check all your measurements before printing. For this purpose you can use the grid tool of illustrator for precise placement of each element.

Impact of dielines in printing process

In a high-volume production run, a dieline acts as your ultimate insurance policy. It protects the brand from the “butterfly effect” where a 1mm error leads to a mountain of un-foldable scrap of paperboard. So, whether you print 50 boxes or 50,000. The dieline ensures that the first box off the press is an identical twin to the last. Some other benefits are:

- By guiding the die-cutting machine where to cut and score, dielines guarantee structural accuracy. Thus the product fits perfectly and arrives safely.

- Dielines save millions of bucks. Because they allow printing more units per sheet. This minimizes the errors, material waste, and lowers the cost per piece.

- Dielines also include “Bleed” areas or lines which help the designers to create high-quality graphics without and white edges or misalignment.

Conclusion

The journey from a digital canvas to a physical storefront is a complex one. Only dielines for packaging make this transition possible. Therefore to achieve retail-ready results that balance beauty with budget, never overlook the technical details of dielines. Because a unique design comes from a perfect line.

.jpg)