What is Die Cutting? A Complete Guide

If you have ever placed an order for your printed anything or are planning on doing so. Then you need to know what is die cutting! In the article, we are going to explain the different processes of die cutting and die cut materials. We will also talk about its disadvantages along with the advantages. We also touch on how is it different than laser cutting.

Die cutting is a process where a special die is used to cut different custom shapes out of a sheet of material. The material is usually paper stock of different kinds. Let's learn about a few important words needed to understand the process.

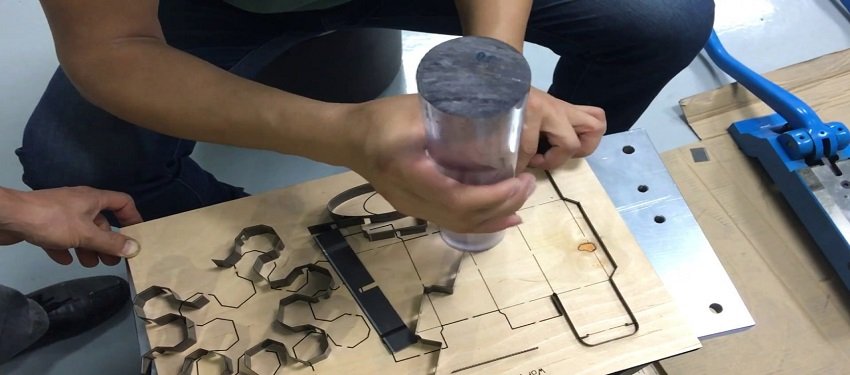

It's not the usual scary word, is a different kind of die! This is basically a tool used to cut the required shape out of stock. You can consider it like a cookie cutter but for paper. They are made of metal with a sharp raised area for cutting.

Again, unlike the movie, this is a rather dull kind of the matrix. After the die has done its job through the sheet of stock. The remaining excess material is called the matrix.

Sounds like a war zone I know! But this die line is simply an outline to mark where the die will cut. It is a thick colored line in proofs mostly. Usually, if you are going for a unique shape and custom dimensions for your label, a new die is required for the first time. This can be used multiple times to cut the perfect custom label over and over again. But if you have a generic size, there is a high possibility that a previous die can be used by the printing company.

Read to Know! What is Cardstock?

There are many kinds of die cutting machines, almost all can cut paper. Most can cut into foam, thin fabric, felt, and vinyl. But you want to cut through chipboard that only the steel rule dies are up to the job. Some machines can even cut flexible stock like leather, rubber, and corkboard.

There are many kinds of processes for die cutting, we are going to talk about the three major ones for printed labels. You can read up on these and decide which suits you the most.

Flatbed die-cutting is essentially done with a lifting system to press a die on the material sheet. Usually, hydraulic pressers are great for it. They are better for heavier materials like metals, fabrics, or felt. It involves manual labour making it less efficient in terms of speed. This is why it is popular for low volume projects.

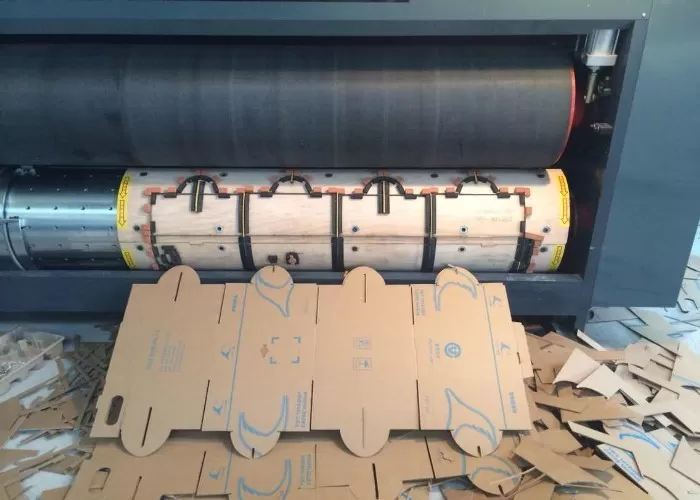

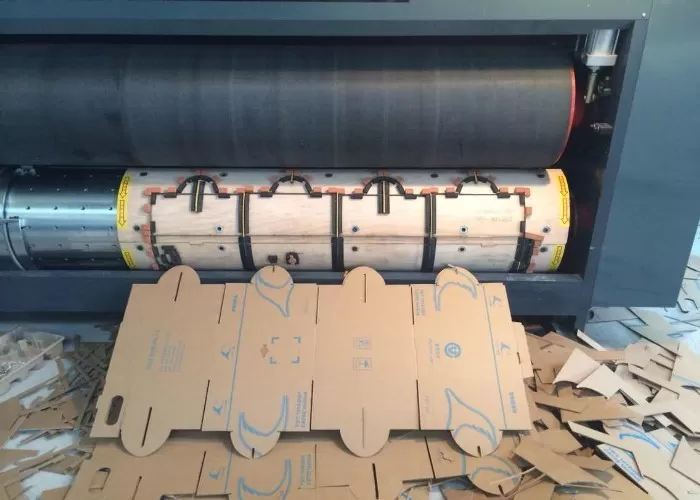

Rotary die cutting uses rolling dies that are attached to a magnetic cylinder. Long flexible sheets of material are rolled through the machine to make cuts. After making the cuts, the rest of the material is pulled away, leaving just the cutout pieces behind. The die continuously rotates and needs to be strictly in sync with the web material's speed. These machines can use solid as well as flexible dies. The magnetic cylinders that are covered with the die design are called solid dies. The flexible dies are thin sheets of metal rolled around a plain cylinder. Making them cost effective and easy to change.

These are much like the rotary die-cutting but here, the die cut plate only covers a part of the cylinder. It means the web waits for the die cut plate and accelerates to the production speed. After the die cutting, it waits again for the next revolution. It uses a single magnetic cylinder and flexible die tools that are interchangeable. It saves the tool cost and takes a shorter time to set up.

Read! What is An Eco Box? - Kraft Eco Boxes

Now let's look at some of the pros and cons of die-cutting.

Some of the advantages of die cutting include its potential to be able to create almost any shape. It is very precise and good for producing bulk orders. Rotary die cutting machines can cut through yards of material in just a few minutes. You can get your own custom plate made for unique packaging ideas. If the die material is good then it can be used for a long time without needing a replacement. Making it affordable in the long run.

The first disadvantage is the chances of physical injuries through the machines. The steel rule and rotary dies, both are very sharp, and mishandling them could result in serious harm. Also, a new die is needed for each design you want. Making it less cost effective for low volume orders. It can also be difficult to cut through thicker materials with precision, causing a tacky outcome.

Now that you know what is die cutting, let's talk about laser cutting and the basic differences. The dies apply pressure and cut through the material. Whereas, laser cut uses a focused beam to melt or burn through it. They both have their pros and cons. Die cutting is ideal for packaging, textiles, or automotive industries because of its speed and efficiency. Laser cut is relatively low but preferred for intricate works like jewelry making, lettering, engravings, and etching.

Now you have a full guide about what is die cutting. You can choose the right material and method for your next project! If you need precise cut prints and custom packaging solutions then check out Boxit Packages. We are experts in what we do and provide free design assistance. We offer a low MOQ, affordable rates, and free delivery all across the USA and Canada.

Must Read! A 5 Steps Guide to Curating a Perfect Unboxing Experience

.jpeg)